Single /Multi -Layer

Extruder Screen packs

Single-layer / Multi-layer Extruder Screen packs :

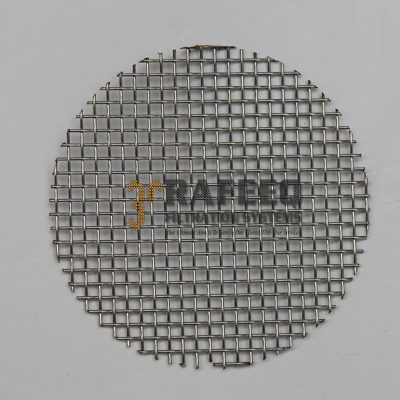

Extruder screens can be made with both one layer of wire mesh or multiple layers.

A single-layer is used when virgin material with few impurities is being processed.

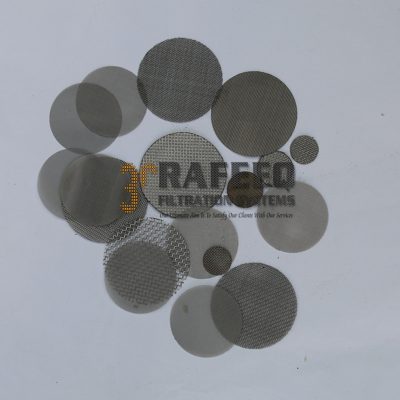

Multilayer Extruder Screen packs are the different wire meshes cut to desired shapes and sizes, and then assembled properly and spot welded with each other to form multilayer packs.

Multi-layer is used when reground or recycled material is being used or when absolute cleanliness is a must. There is typically a more coarse protection layer that the melted polymer first comes in contact with.This protects the finer filtration layer or layers from debris damage, pressure, or the swirling motion of the plastic melt. Another coarse layer faces the breaker plate to support and protect the finer mesh layer from being pushed into the breaker plate holes.

Configurations vary depending on a wide variety of factors, such as material type and cleanliness requirements, but extruder screens typically contain 2 to 5 layers.

That layer could be held together with spot welds, a rim-binder, welded with frame or the layers could simply be unsecured and stacked in the desired configuration.

This type of extruder screen is suitable for fine extrusion, and it makes extrusion more clean and clear.

Features:

- No burrs and easy to operate.

- Made into a variety of shapes.

- Accurate pore size.

- Accurate micron ratings.

- High Stability and durability.

- Capability to hold dirt.

- Corrosion resistance.

Extruder Screen packs with Frame /Rim :

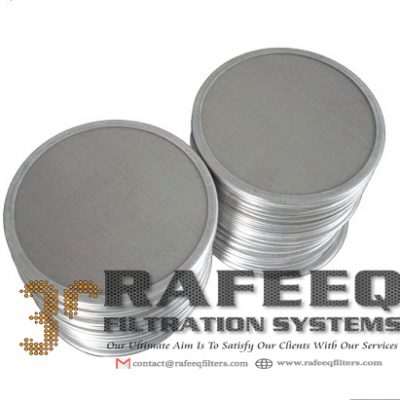

Extruder screen packs feature spot-welded packs with an Aluminium or Stainless Steel rim added for extra rigidity and strength.

Rim / Frame Extruder screens can be made with both one layer of wire mesh or multiple layers.

These are excellent for use where the extruder screen filter is operating at high pressures or if there is a danger of contamination getting around the edge of the breaker plate.

This multilayer extruder screens packs are welded together at precise points. They are excellent for use in any filtration and assembled in proper sequence to eliminate operator error. The number and location of spot welds can be customized for your process.

Features:

- Abrasion resistance and can be operated under high pressure.

- Stable and has high capacity.

- Accurate pore size.

- Accurate micron ratings.

- Flat edge and solid structure.

- High Stability and durability.

- Capability to hold dirt.

- Corrosion resistance.

- Excellent filtration efficiency.

Rubber Framed Extruder Screen pack :

Rubber Framed Extruder Screen pack :

Rubber framed extruder screen possesses an elastic edge that make it become strong and stable. And the screens are more economical than the metal framed screens and also can be designed into a variety of shapes.

Flexible structure gives rubber framed extruder screen good strain resistance. What’s more, rubber framed extruder screens have excellent filtering ability in plastic extrusion, chemical fiber filtration, water treatment.

Tri-clamp screen gaskets are designed to be interchangeable with standard sanitary clamp gaskets to protect pump, values and other components in fluid line.

It has the widest ranges of mesh sizes for excellent and efficient particulates collection and filtration in water, acetones and ketones transmission.

EPDM, PTFE, viton and silicon gasket material options supply perfect performance in corrosive and chemical fluid transmission.

Features:

- Abrasion resistance and can be operated under high pressure.

- Stable and has high capacity.

- Accurate pore size.

- Accurate micron ratings.

- Flat edge and solid structure.

- High Stability and durability.

- Capability to hold dirt.

- Corrosion resistance.

- Excellent filtration efficiency.

PRODUCT SPECIFICATIONS

Product Name:

Extruder Screen packs /spin pack filters

Brand :

3R

Material:

• Stainless Steel 304/316L ,

•black wire cloth,

• copper,

• brass Etc.

Packs Diameter :

• 20 MM - 900 MM

Frame/Rim style:

• with and without frame and spot welding etc.

Micron Rating:

5 to 1000 micron

Layers:

single layer or spot welded multi-layer screen discs.or with edges.

Major types:

• Single Layer Extruder Screen;

• Multilayer Extruder Screen Packs;

• Single Layer Extruder Screen with Frame;

• Multilayer Extruder Screen Packs

with Spot Welded or Frame Edges;

• Rubber Framed Extruder Screen ;

• Tri-Clamp Screen Gaskets

Shapes:

• circular,

• square,

• rectangle,

• kidney shape,

• Ring-shaped,

• Cylindrical,

• cones,

• bowl,

• disc,

• other special shapes.

Edge Material:

• Aluminium,

• rubber,

• brass etc.

Frame/Rim Thickness:

2 to 5 MM

Layers:

2 , 3 ,4, 5 layers

Mesh Types:

• Woven Wire mesh.

• Fine Mesh.

• Coarse Mesh.

Weave Types

• Plain Weave.

• Dutch Weave.

• twill weave etc.

Usage:

It is widely used in filtration of plastics and rubber processing industry, chemical and pharmaceutical industry

APPLICATIONS

Some examples are:

Reclamation of Plastic Waste:

The new plastic ‘raw’ material is gained by heating waste plastic and passing it through an extruder screen filter within a plastic extrusion machine. The extruder screen filter removes contaminants such as paper, allowing the clean recycled plastic to be collected at the end of the process.This can then be manufactured into a new product which has reduced the negative impact of using new plastic material.

Extruded Profiles

Wire mesh extruder screen filters are extensively used in the extrusion of plastic profiles. Applications include UPVC window profiles, plastic tubing ranging from gutters to industrial utility pipes and custom made extrusions.

Blown Film Extrusion

Extruder screen filters are used in the production of polythene bags, waste sacks and plain ‘cling’ film to name but a few. The wire mesh extrusion filters are an essential part of this process as they remove any remaining impurities in the plastic so that the end product does not have any flaws in it.

• Polyester Oriental Yarn.

• Polyester Stable Fibers.

• Polypropylene Yarn.

•Nylon and Acrylic Yarn.

• BCF Polypropylene Yarn.

• Polypropylene Spun bonded Non-woven Fabrics.

• Polyester fiber production.

• chemical and pharmaceutical industry.

• Oil and fuel filtration.

• Extrusion in lamination plants.

• Extrusion in Multilayer film plants.

Address List

- 7-2-221/16, Ashok Colony, Sanathnagar,Hyderabad-500018.

- +91-7032799545

-

[email protected]

[email protected]

Social Networks

Rafeeq Filtration Systems

Our Ultimate aim is to satisfy Our Clients With Our Services.