Extruder Screen pack By Shape

Circle Extruder screens Pack:

Circle Extruder screens are available in different size, variants and specifications.

Extruder screens are an imperative part of the melt filtration process. It is used in plastic and rubber processing machinery to ensure a clean and viable extrusion. Our wire cloth screen for extruder filtration available in various materials, weaves all with a wide spectrum of micron ratings to suit different filter use. Also called polymer filter or melt filter screen

Single layer extruder screens are predominantly used in the extruded profiles and blown film industries where the contamination of the raw material is less and there is often lower pressure within the extruder head.

Many single layer screens are assembled properly and spot welded with each other to form multilayer. It can be with or without selvage. Multilayer extruder screen is used for fine and thin level of extrusion to prevent the mixing of foreign particles. Multilayer Extruder Screen helps in making extrusion more clear and clean.

Circle extruder screens benefits:

- Smooth screening surface with no sharp edges, burrs or acute angles.

- High durability and are stable under tension.

- Cut uniformly to avoid uneven edge.

Applications of circle extruder screen:

- Keeps away mixing of foreign particles in finally equipped extrusion product.

- Provide a clean and clear extrusion.

- Mainly used in plastic processing, chemical, rubber and pharmaceutical industries.

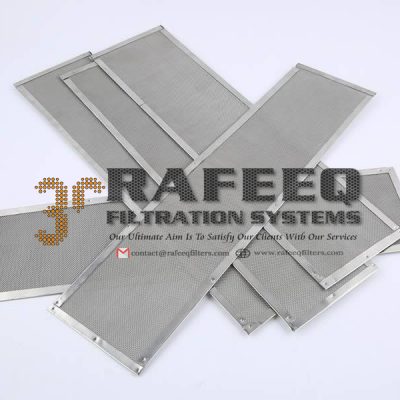

Rectangle & Oval - shaped Extruder Screens Pack:

Rectangle and oval-shaped extruder screens are commonly made from stainless steel wire that has good rust and corrosion resistance.

Rectangle and oval-shaped extruder screen features:

- Accurate shape dimension well fit the corresponding extruder.

- Easy to install and durable.

- High compressive strength.

Rectangle and oval-shaped extruder screen applications:

- Provide a clean and fine extrusion of molten materials, polymers.

- Suitable for filtration in plastic, leather, metallurgy and petroleum industries.

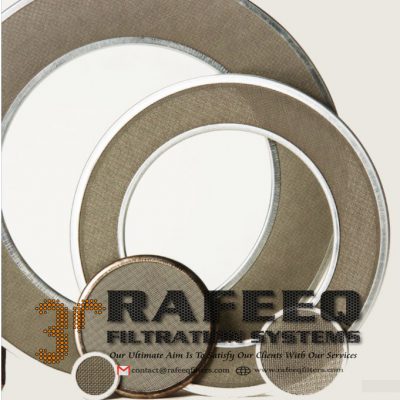

Ring-shaped Extruder Screen Pack:

Ring-shaped extruder screen is generally made from stainless steel, aluminum or copper and can be manufactured into various sizes and layers to ensure its precision.

With standard structure and flexibility, ring-shaped extruder screens are easy to fit your extruder or even other filter equipment, which can well keep away impurities from molten materials or other industrial materials.

Specifications of ring-shaped extruder screen:

- Materials: stainless steel, aluminium, copper or brass.

- Inner diameter: 18–250 mm.

- Outer diameter: 50–350 mm.

- Layer: single layer or multiple layers.

- Edge: with rims or no rim or welded.

- Filter accuracy: 2–1000 μm.

Ring-shaped extruder screen features:

- Lightweight and easy to operate.

- Accurate filter precision.

- High temperature resistance and high tensile strength.

Ring-shaped extruder screen applications:

- Give clean and ideal extrusion to melt plastic, chemical fiber, adhesive or ceramics.

- Meet corresponding requirements of filtration scenario such as in oil, metallurgy, medicine industries.

Kidney-shaped Extruder Screen Pack:

Kidney-shaped extruder screen is a special shape of filter which can be made of a variety of materials. So you can customize a type according to application requirements.

With unique shape, kidney-shaped extruder screen with single layer can be used in blown film industry in which has small pressure. Multiple layers of kidney-shaped extruder filter screens are more solid that can be used several times in plastic, fiber, glass industries.

Specifications of kidney-shaped extruder screen:

- Materials: stainless steel wire mesh, black wire cloth, aluminum wire mesh, alloy wire mesh.

- Layers: single layer or multiple layers.

- Sizes: custom made.

Kidney-shaped extruder screen features:

- Special shape and function.

- Reusable and durable.

- Accurate filter precision.

Kidney-shaped extruder screen applications:

- Extrusion and reclamation of plastic, glass.

- Show its abilities of film coating and filtration in blown film, pharmaceutical, oil industries.

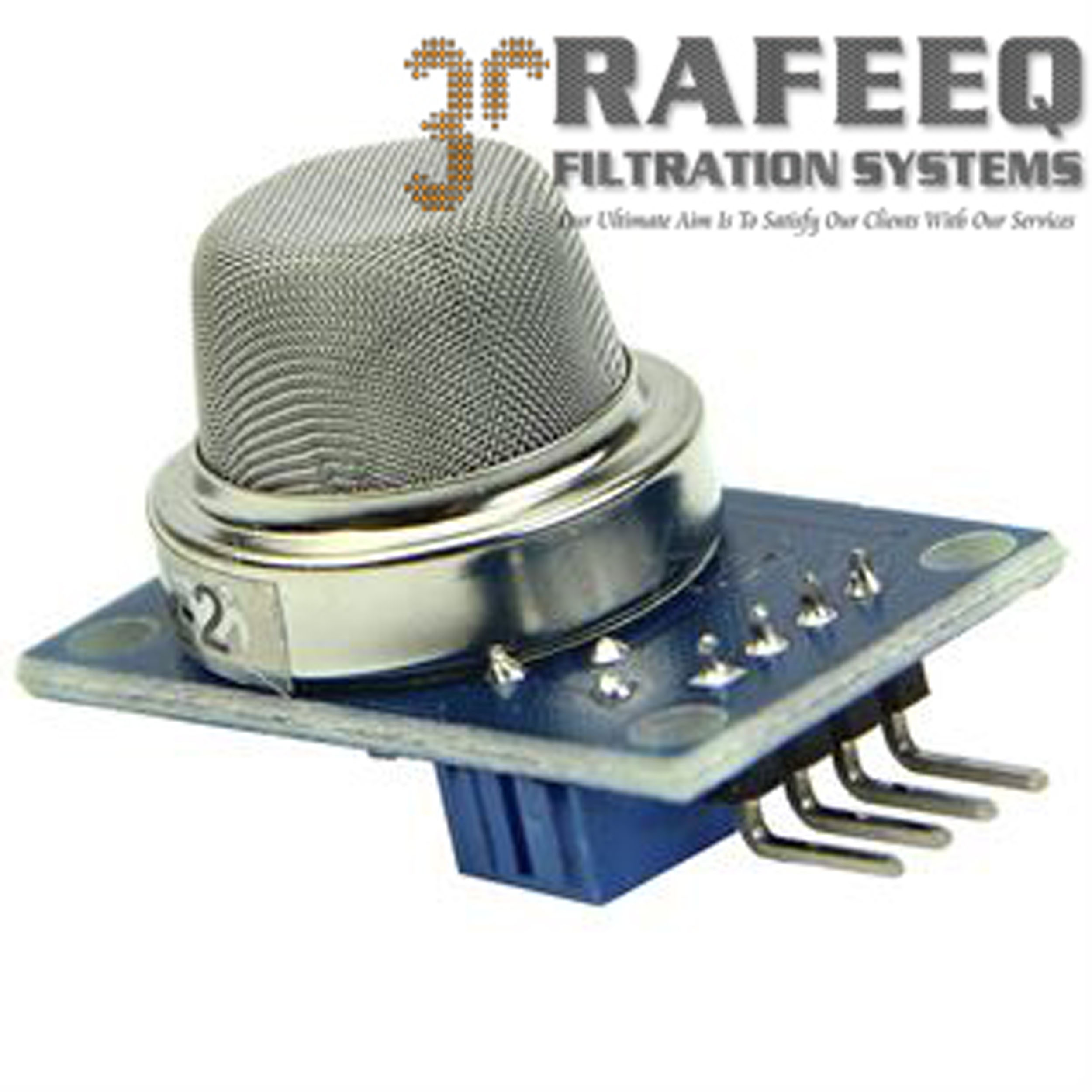

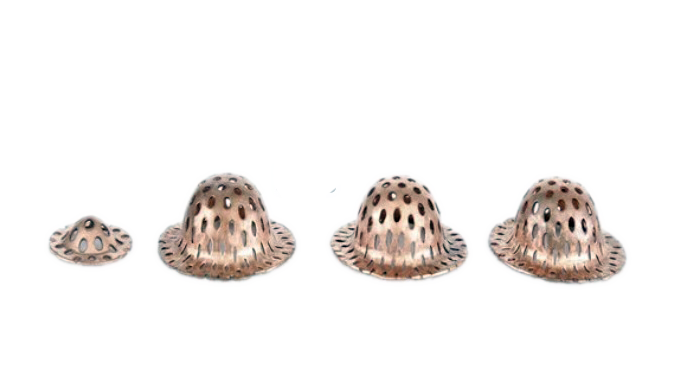

Bowl / Dome shaped Extruder Screen Pack:

Bowl/Dome-shaped extruder screen is a special shape of filter which can be made of a variety of materials. So you can customize a type according to application requirements.

Also Called as Pipe screens filter.

Specifications of Bowl/Dome-shaped extruder screen:

- Material Type: Brass/Copper wire mesh, stainless steel wire mesh 304,304l,316,316l wire mesh.

- Shape : bowl-shaped, Dome-shape etc.

- Size can be customized.

Bowl/Dome-shaped extruder screen features:

- Special shape and function.

- Reusable and durable.

- Accurate filter precision.

- High temperature resistance.

- Corrosion resistance

Bowl/Dome-shaped extruder screen applications:

- Used for medical and chemical industry as filter mesh.

- Used in pipes and stops embers and tobacco from travelling up the pipe and into your mouth.

- Smoking pipe screen.

- Gas detection sensor cover.

- Aerospace filed.

Pipe screens are used in your pipes and stop hot embers and tobacco from traveling up the pipe and into your mouth.

Also help prevent the formation of dottle, a wet and sour clump of tobacco that can potentially ruin a pipe.

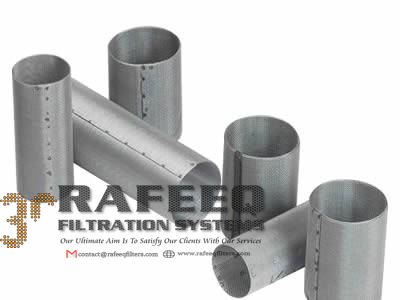

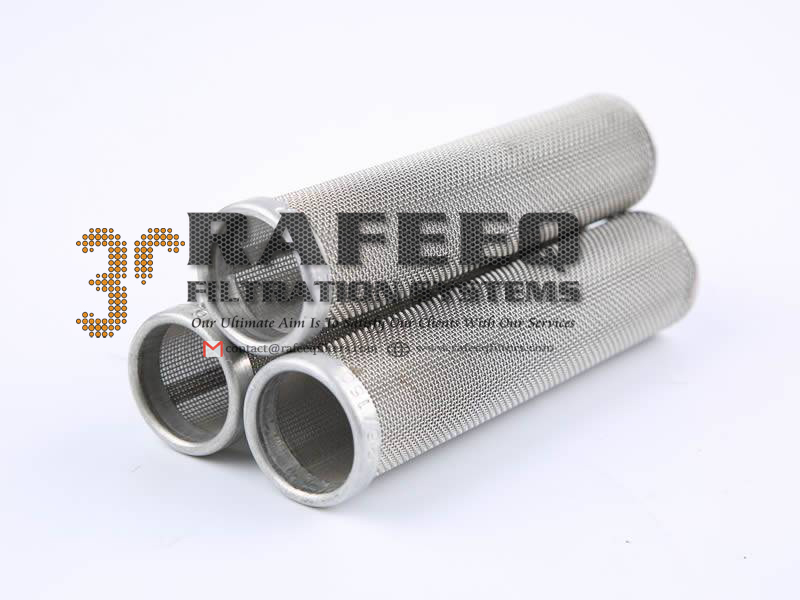

Cylindrical Extruder Screen Pack:

Cylindrical screenpacks also known as filter tube, is made of wire mesh and then is rolled into tube shape. According to the material, it can be classified into stainless steel tube filter, copper tube filter, black wire cloth tube filter, galvanized steel tube filter, etc.

According to the processing technology, it can be classified into woven tube filter, perforated tube filter, expanded metal tube filter, etc. Among these products, stainless steel tube filter and black wire cloth tube filter is more popular than other types.

With accurate filtration rate, tube filter can filter a large variety of fluids and retain almost any size solids. With high mechanical strength, tube filter is mainly used in pipeline filtration, petroleum, chemical industry, pharmacy, food making filtration and sewage water filtration, etc.

Specifications

Product Name:

Extruder Screen packs /spin pack filters

Brand :

3R

Material:

• Stainless Steel 304/316L ,

•black wire cloth,

• copper,

• brass Etc.

Packs Diameter :

• 20 MM - 900 MM

Frame/Rim style:

• with and without frame and spot welding etc.

Micron Rating:

5 to 1000 micron

Layers:

single layer or spot welded multi-layer screen discs.or with edges.

Major types:

• Single Layer Extruder Screen;

• Multilayer Extruder Screen Packs;

• Single Layer Extruder Screen with Frame;

• Multilayer Extruder Screen Packs

with Spot Welded or Frame Edges;

• Rubber Framed Extruder Screen ;

• Tri-Clamp Screen Gaskets

Shapes:

• circular,

• square,

• rectangle,

• kidney shape,

• Ring-shaped,

• Cylindrical,

• cones,

• bowl,

• disc,

• other special shapes.

Edge Material:

• Aluminium,

• rubber,

• brass etc.

Frame/Rim Thickness:

2 to 5 MM

Layers:

2 , 3 ,4, 5 layers

Mesh Types:

• Woven Wire mesh.

• Fine Mesh.

• Coarse Mesh.

Weave Types

• Plain Weave.

• Dutch Weave.

• twill weave etc.

Usage:

It is widely used in filtration of plastics and rubber processing industry, chemical and pharmaceutical industry

APPLICATIONS

Some examples are:

Reclamation of Plastic Waste:

The new plastic ‘raw’ material is gained by heating waste plastic and passing it through an extruder screen filter within a plastic extrusion machine. The extruder screen filter removes contaminants such as paper, allowing the clean recycled plastic to be collected at the end of the process.This can then be manufactured into a new product which has reduced the negative impact of using new plastic material.

Extruded Profiles

Wire mesh extruder screen filters are extensively used in the extrusion of plastic profiles. Applications include UPVC window profiles, plastic tubing ranging from gutters to industrial utility pipes and custom made extrusions.

Blown Film Extrusion

Extruder screen filters are used in the production of polythene bags, waste sacks and plain ‘cling’ film to name but a few. The wire mesh extrusion filters are an essential part of this process as they remove any remaining impurities in the plastic so that the end product does not have any flaws in it.

• Polyester Oriental Yarn.

• Polyester Stable Fibers.

• Polypropylene Yarn.

•Nylon and Acrylic Yarn.

• BCF Polypropylene Yarn.

• Polypropylene Spun bonded Non-woven Fabrics.

• Polyester fiber production.

• chemical and pharmaceutical industry.

• Oil and fuel filtration.

• Extrusion in lamination plants.

• Extrusion in Multilayer film plants.

Address List

- 7-2-221/16, Ashok Colony, Sanathnagar,Hyderabad-500018.

- +91-7032799545

-

[email protected]

[email protected]

Social Networks

Rafeeq Filtration Systems

Our Ultimate aim is to satisfy Our Clients With Our Services.